Selecting between dry and oiled filter intakes depends on application needs. Dry filters, using materials like paper or cotton, prevent oil or moisture damage and are easy to maintain by replacing the media. Oiled filters, with a coated media, capture smaller particles efficiently but require regular oil cleaning or replacement due to clogging resistance. Understanding these differences is crucial for optimal filtration system performance in diverse settings, from automotive to industrial uses.

In the realm of automotive filtration, understanding the nuances between dry and oiled filter intakes is paramount. This article delves into the heart of these systems, illuminating their distinct designs and functions. We explore how each type impacts engine performance through varied conditions, shedding light on maintenance requirements and costs. By comparing dust capture rates, debris removal, and oil’s role in airflow optimization, this guide offers insights crucial for drivers and mechanics alike, highlighting the benefits of dry filter vs oiled filter intakes.

- Dry Filter vs Oiled Filter Intakes: Understanding the Basics

- – Definition of dry and oiled filter intakes

- – Key differences in design and function

Dry Filter vs Oiled Filter Intakes: Understanding the Basics

In the realm of filtration, understanding the nuances between different types is crucial for selecting the most effective system. When it comes to dry versus oiled filter intakes, each has its own unique characteristics and applications. A dry filter intake operates by using a dry media, such as paper or cotton, to capture contaminants. These filters are typically easy to maintain, requiring only regular replacement of the media. They are ideal for applications where oil or moisture could damage equipment or introduce unwanted substances, like in some automotive and industrial settings.

In contrast, oiled filter intakes employ a layer of oil to trap particles. The oil creates a barrier that allows contaminants to adhere to its surface, preventing them from passing through. This type of filter is commonly used in systems where dust or fine particles are prevalent, as the oil helps prevent clogging and ensures a steady flow. Despite their effectiveness, oiled filters require more meticulous care, including periodic cleaning or replacement of the oil, to maintain optimal performance.

– Definition of dry and oiled filter intakes

In the realm of filtration systems, understanding the distinction between dry and oiled filter intakes is paramount for optimal performance. Dry filter intakes refer to air filters that do not use any oil or lubricants to trap particles. These filters rely solely on fibrous media, such as cotton or synthetic blends, to capture contaminants like dust, pollen, and dirt. Oiled filter intakes, on the other hand, employ a coating of oil or grease on the filter media to enhance its efficiency. This simple yet effective technique allows smaller particles to adhere to the oily surface, preventing them from escaping through the filter.

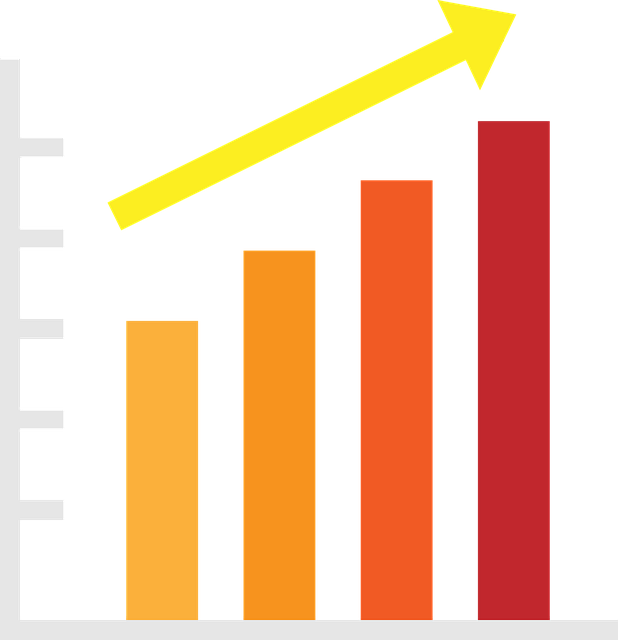

The choice between dry and oiled filters depends on specific application requirements. Dry filters excel in environments where oil-soluble contaminants are minimal, ensuring consistent airflow without the need for regular oil changes. Oiled filters, however, prove indispensable in industries or conditions with high levels of oil mist or dust, as they capture smaller particles more efficiently and require less frequent replacement. Thus, understanding this difference is crucial when selecting a filtration system to ensure its effectiveness in any given setting.

– Key differences in design and function

In the realm of filtration, one key distinction lies in the design and function between dry and oiled filter intakes. Dry filters, as the name suggests, operate without any oil or lubricant, relying solely on a combination of media such as cotton, synthetic materials, or blends to capture contaminants. These filters are typically more lightweight, offering easier installation and replacement. They are often preferred in applications where regular maintenance is feasible, like in everyday vehicle intakes, due to their straightforward design.

On the other hand, oiled filter intakes incorporate oil into their filtration process. The oil acts as a separator, slowing down incoming particles and allowing them to settle before being trapped by the media. This design is more complex but offers several advantages. Oiled filters can capture finer particles and are less likely to clog rapidly, making them suitable for high-flow or heavy-duty applications. They also tend to provide a longer service life, although they may require periodic oil changes to maintain optimal performance.

In comparing dry filter vs oiled filter intakes, understanding their distinct design and function is key. Dry filters, with their simple, maintenance-free nature, offer efficient particle capture, making them ideal for clean environments. Conversely, oiled filters excel in harsh conditions, providing superior dust hold capacity due to their intricate design and oil coating. The choice between these two depends on specific needs, be it for industrial applications or automotive use. Both have their merits, ensuring optimal performance when selected appropriately for the task at hand.